Definition: Food safe epoxy is a type of resin that is specifically formulated to be safe for use in food-contact surfaces. It is commonly used in various applications, such as countertops, cutting boards, and kitchen tools, where it can come in direct contact with food. The epoxy is designed to be non-toxic and resistant to heat, moisture, and chemicals, making it an ideal material for environments where hygiene and durability are essential.

Importance of food safety: Food safety is critical in any environment where food is prepared, served, or processed.By ensuring that toxic chemicals or other dangerous substances do not seep into the food, food safe epoxy protects customers and complies with health requirements.This is especially important in kitchens, restaurants, and food manufacturing settings, where sanitation standards must be strictly maintained.

Context: Not all epoxies are food-safe, and the distinction is crucial. Regular epoxy resins may contain harmful substances that can contaminate food, making it essential to use only those that meet food safety standards. Choosing food safe epoxy guarantees that the surfaces are both functional and safe for food-related applications.

What Is Epoxy?

General overview: Epoxy resin is a durable and versatile material known for its strong adhesive properties and ability to create tough, long-lasting coatings. It’s made by mixing two components: resin and hardener, which chemically bond to form a solid, durable substance. Epoxies are used in a wide range of applications due to their strength, including countertops, flooring, jewelry making, and coating various surfaces like wood, metal, and plastic.

Common applications: Epoxy resin is used extensively in many different industries, however not all varieties are suitable for surfaces that come into contact with food. Most standard epoxies contain harmful chemicals, such as bisphenol-A (BPA), or other substances that can leach into food when exposed to heat or moisture. These chemicals can pose health risks, making them unsuitable for applications where the resin will come into direct contact with food. Therefore, it is important to ensure that epoxy used in food-related products is properly labeled as food-safe.

What Is food safe epoxy?—-Food safe epoxy is a type of resin specifically formulated to be non-toxic and safe for use on surfaces that come into direct contact with food. Unlike regular epoxy, which may contain harmful chemicals like bisphenol-A (BPA) or other substances that can leach into food, food-safe epoxy is designed to meet strict safety standards. It is commonly used in environments like kitchens, restaurants, and food processing areas to coat countertops, cutting boards, and other surfaces where food is prepared or served. Food safe epoxy is durable, resistant to heat and moisture, and ensures that no harmful substances are transferred to food, providing a safe and long-lasting solution for food-related applications.

What Makes Epoxy Food Safe?

Ingredients of food-safe epoxy: Food safe epoxy differs from regular epoxy in the ingredients used and the standards it meets for safety. A resin and a hardener are the two primary ingredients of both varieties of epoxy. On the other hand, non-toxic materials used to make food-safe epoxy make it safe to come into direct touch with food when it has completely dried. The key difference lies in the selection of materials used to create food-food safe epoxy, ensuring that harmful chemicals like bisphenol-A (BPA) or other toxic substances are excluded.

Certification: Food-safe epoxies are often tested and certified by regulatory bodies, such as the U.S. Food and Drug Administration (FDA), or other similar organizations in different countries.These certificates attest to the epoxy’s compliance with particular safety requirements for applications involving food.

Non-toxicity after curing: It’s essential for food safe epoxy to be properly mixed and fully cured before coming into contact with food. During the curing process, any potentially harmful substances are neutralized, and the epoxy becomes safe for use. Incomplete curing or improper mixing can result in a product that is still harmful, so following the manufacturer’s instructions is crucial to ensure the epoxy is non-toxic and safe for food-contact surfaces.

How to Choose Food-Safe Epoxy

When choosing food-safe epoxy, it’s essential to ensure that the product meets safety standards to protect your health. Here are some key factors to consider:

- Look for Certifications: Always check the product label for certifications that confirm it meets food-safe standards. For example, FDA approval indicates that the epoxy is safe for food-contact surfaces, while NSF (National Sanitation Foundation) certification ensures it meets specific safety criteria for use in food establishments. These certifications provide peace of mind that the epoxy has been tested and approved for safe use with food.

- Brands and Recommendations: Several well-known brands specialize in food-safe epoxies. Popular options include TotalBoat TableTop Epoxy, ProMarine Supplies Epoxy Resin, and ArtResin. These products are highly rated for their food-safe qualities and are commonly used for countertops, cutting boards, and other kitchen applications. Be sure to read reviews or consult recommendations from reliable sources to find the best product for your needs.

- Curing Time: The curing process is crucial in making sure the epoxy is safe to use. The curing time can vary depending on the product, but typically, food-safe epoxy needs at least 24-72 hours to fully cure. Before employing epoxy in food-related applications, it must be allowed to fully solidify. A surface that has not been fully cured may become sticky or dangerous. Always follow the manufacturer’s instructions for curing times to ensure the epoxy is completely hardened and safe for use.

Here’s a shortened version of how to choose food-safe epoxy:

| Factor | Description |

| Certifications | Look for FDA approval or NSF certification to ensure the epoxy is safe for food contact and meets safety standards. |

| Brands & Recommendations | Popular brands like TotalBoat, ProMarine, and ArtResin are known for their food-safe qualities. Check reviews or trusted sources for recommendations. |

| Curing Time | food safe epoxy typically needs 24-72 hours to cure fully. Ensure complete curing for a safe, non-sticky surface. Follow manufacturer instructions. |

Applications of Food-Safe Epoxy

Countertops and tabletops: Food-safe epoxy is a versatile material that is commonly used in various food-related applications. One of the primary uses is for coating countertops, tabletops, and cutting boards. Its durable, non-toxic finish helps protect surfaces from moisture, stains, and heat, while ensuring safety when in contact with food. This makes food safe epoxy ideal for kitchen environments, where hygiene and durability are essential.

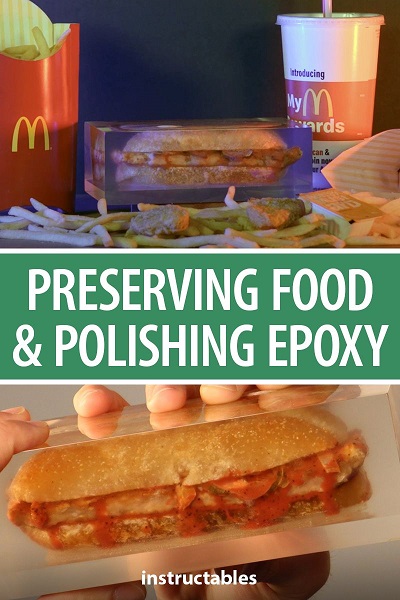

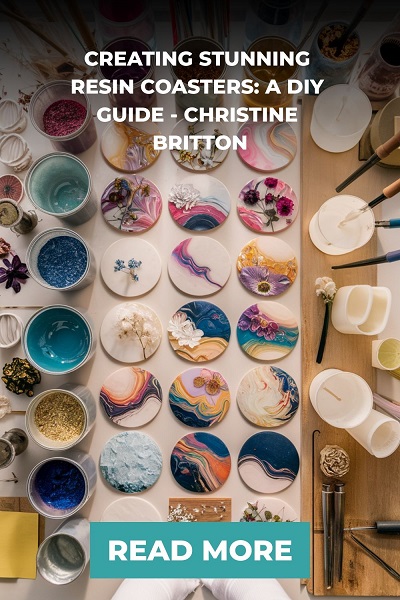

DIY projects: In DIY projects, hobbyists and craftspeople often use food-safe epoxy to create custom kitchen tools like resin cutting boards, serving trays, and coasters. The epoxy can be molded into different shapes and sizes, allowing for creative designs that are both functional and food-safe. It provides a glossy, smooth finish while adding a touch of personalization to kitchen items.

Repairs and renovations: Food safe epoxy is also popular for repairs and renovations. If kitchen items like bowls, plates, or utensils get cracked or damaged, food safe epoxy can be used to restore them to their original condition. It creates a strong, seamless bond that is safe for food contact once properly cured, making it an excellent choice for extending the life of kitchenware.

Here’s a shortened version of the applications for food-safe epoxy:

| Application | Description |

| Countertops & Tabletops | Protects surfaces from moisture, stains, and heat while ensuring food safety in kitchens. Ideal for countertops, tabletops, and cutting boards. |

| DIY Projects | Used to create custom kitchen tools (cutting boards, trays, coasters) with a glossy finish, allowing for creative, food-safe designs. |

| Repairs & Renovations | Repairs cracked kitchenware (bowls, plates, utensils) with a strong, seamless bond that’s safe for food contact once cured. |

How to Apply Food safe epoxy

Applying food safe epoxy correctly ensures a smooth, durable, and safe surface. Here’s a step-by-step guide on how to apply food safe epoxy:

Preparation:

The surface must be adequately prepared before epoxy is applied. Start by thoroughly cleaning the area to remove dust, dirt, grease, or oil. If you’re applying the epoxy to wood, plastic, or another porous material, lightly sand the surface to create a rough texture, allowing the epoxy to bond better. Make sure the surface is totally dry before applying anything.

Mixing and Applying:

When your surface is prepared, combine the resin and hardener as directed by the manufacturer.Typically, the ratio is 1:1, but always check the specific guidelines on the product you’re using. Mix the two components thoroughly in a clean container for several minutes, scraping the sides of the container to ensure even mixing. After mixing, carefully pour the epoxy onto the surface, starting from the center and working your way out. Use a brush, roller, or spreader to evenly distribute the epoxy, ensuring it covers the entire area. Be mindful of any air bubbles that may form and use a heat gun or torch to gently remove them.

Safety Precautions:

Always prioritize safety when working with epoxy.To prevent skin contact with the resin and hardener, put on protective gloves. Since the fumes can be harmful, especially during mixing, it’s recommended to wear a respirator or work in a well-ventilated area. Additionally, make sure to wear protective eyewear to shield your eyes from any potential splashes. To guarantee a safe working environment, adhere to all safety guidelines supplied by the manufacturer.

Here’s a shortened version of the guide for applying food safe epoxy:

| Step | Instructions |

| Preparation | Clean the surface thoroughly (remove dust, dirt, grease). If using on porous materials (wood, plastic), lightly sand for better bonding. Ensure surface is dry. |

| Mixing & Applying | Mix resin and hardener (usually 1:1 ratio) thoroughly for several minutes. Pour epoxy onto surface, starting from the center and spreading evenly. Remove air bubbles with a heat gun. |

| Safety Precautions | Wear gloves, protective eyewear, and a respirator. Work in a well-ventilated area. Follow manufacturer’s safety guidelines. |

Advantages of Food-Safe Epoxy

Food safe epoxy offers a variety of advantages that make it an ideal choice for a wide range of applications, especially in food-related environments.

- Durability: One of the primary benefits of food safe epoxy is its strength and resistance to wear and tear. Once cured, it creates a solid, long-lasting surface that can withstand heavy use, including cutting, chopping, and other food preparation activities. It is also resistant to moisture, heat, and chemicals, making it perfect for high-traffic areas like kitchen countertops. Its ability to endure extreme temperatures ensures it won’t warp or degrade under typical kitchen conditions, maintaining its integrity over time.

- Aesthetics: Food safe epoxy enhances the visual appeal of kitchen surfaces. Its glossy finish provides a sleek, polished look that adds sophistication to countertops, cutting boards, and tabletops. The resin can also be tinted or mixed with decorative elements like pigments, glitter, or wood inlays, offering endless creative possibilities. This makes it a popular choice for both functional and aesthetic purposes, transforming ordinary surfaces into custom-designed, beautiful focal points in the kitchen.

- Versatility: Beyond kitchens, food safe epoxy is incredibly versatile. It’s used in a wide range of applications, from DIY crafts and art projects to repairing items in other areas of the home. It can be used to create resin art, custom serving trays, coasters, and even jewelry. Additionally, food-safe epoxy is ideal for repairing damaged kitchenware, such as bowls or utensils, extending their lifespan. Its adaptability makes it an essential material for both practical uses and creative endeavors.

Here’s a concise table summarizing the advantages of food-safe epoxy:

| Advantage | Details |

| Durability | Strong and resistant to wear, heat, moisture, and chemicals. Ideal for high-traffic areas like countertops. |

| Aesthetics | Glossy finish enhances the visual appeal; can be tinted or mixed with decorative elements for custom designs. |

| Versatility | Suitable for various applications, including DIY crafts, art projects, repairs, and custom kitchenware. |

Potential Risks and Considerations

While food safe epoxy offers many benefits, there are potential risks and considerations that must be kept in mind to ensure its safe use over time.

- Improper Curing: One of the most important factors in ensuring food-safe epoxy is safe is proper curing. Incomplete curing can result in harmful substances remaining in the epoxy, making it unsafe for food contact. Because of this, it is crucial to carefully follow the manufacturer’s recommendations and let the epoxy dry completely before putting it in touch with food. If the curing process is rushed or the epoxy hasn’t fully hardened, it can release toxins that could contaminate food and pose health risks.

- Maintenance: To maintain the safety and longevity of food-safe epoxy, proper care is necessary. Over time, the epoxy can become damaged or worn down due to frequent use. It’s important to avoid exposing food safe epoxy to excessive heat or harsh chemicals, as these can cause the epoxy to degrade or release harmful substances. For example, placing hot pots or pans directly on epoxy-coated surfaces can cause them to warp or break down. Cleaning the surface with mild soap and water is recommended to avoid damaging the coating.

- Environmental Impact: As with any resin-based material, it’s crucial to consider the environmental impact of food safe epoxy. While some epoxies are more eco-friendly than others, the disposal of epoxy products should be handled responsibly. Cured epoxy is generally safe, but uncured resin and hardener components can be harmful to the environment if not disposed of correctly. It’s important to follow local recycling and disposal guidelines to minimize the environmental footprint and look for epoxy brands that use sustainable or low-VOC (volatile organic compounds) materials.

Here’s a summary of potential risks and considerations regarding food-safe epoxy in a table format:

| Risk/Consideration | Details |

| Improper Curing | Incomplete curing can result in harmful substances, making the epoxy unsafe for food contact.Always follow the manufacturer’s directions for proper curing. |

| Maintenance | Over time, food safe epoxy can wear down. Avoid excessive heat or harsh chemicals, and clean with mild soap and water to maintain its safety. |

| Environmental Impact | Always follow the manufacturer’s directions for proper curing.Dispose of epoxy responsibly and look for eco-friendly options. |

Comprehensive Guide to Food-Safe Epoxy

When it comes to working with epoxy in food-contact applications, it’s crucial to select the right product that ensures safety and durability. Here’s an in-depth guide covering everything from where to find food-safe epoxy to answers to frequently asked questions.

Here’s some key information:

1. Epoxy Food Safe

Epoxy food safe refers to epoxy resins that are certified safe for use in food-contact surfaces, ensuring they won’t leach harmful substances. Always check if the epoxy is FDA-approved or labeled as non-toxic after curing.

2. Epoxy Safe for Food

Epoxy safe for food is designed to be used in environments where food may come into contact with the surface. For safety, ensure that it is FDA-approved and cured according to the manufacturer’s instructions.

3. Epoxy Resin Crystal Clear Art 1 Gallon Food Safe

Crystal clear epoxy resin for art projects is available in gallon sizes and can be food safe if it is specifically designed for food-contact surfaces. Always ensure that it is FDA-approved and non-toxic after curing.

4. Food Safe Epoxy for Ceramics

Food safe epoxy for ceramics is used to bond or repair ceramic items like mugs, bowls, and plates. Be sure to check the product for certifications such as FDA approval to guarantee safety for food use.

5. Food Safe Epoxy Resin FDA Approved NZ

FDA-approved epoxy resin in New Zealand (NZ) is tested and compliant with safety standards, ensuring it is non-toxic and suitable for food contact when properly cured.

6. Food Safe Ceramic Epoxy

Food-safe ceramic epoxy is used for repairs or coatings on ceramics that will be used in food-contact situations. To guarantee safety, always make sure the product has FDA approval.

7. Food Safe Epoxy for Wood

Food safe epoxy for wood is typically used for sealing or repairing wooden surfaces such as countertops and cutting boards. This epoxy is safe for food use once fully cured.

8. Epoxy Resin Safe for Food

Epoxy resin safe for food is an epoxy formulated to be non-toxic once it’s cured.Cutting boards, countertops, and kitchen surfaces are the usual places to utilize it. For piece of mind, always be sure the FDA has approved it.

9. Food Safe Epoxy Adhesive

Food safe epoxy adhesive is used to bond materials together in food-related applications. It’s important to ensure that the adhesive is FDA-approved for food contact after curing.

10. Food Safe Epoxy Glue

Food safe epoxy glue is used for repairs or bonding surfaces in food-contact applications. Make sure the glue is FDA-approved to ensure it’s safe to use in kitchens and food prep areas.

11. Food Safe Epoxy Ceramic

Food-safe epoxy for ceramics is designed specifically for bonding ceramic materials that will be exposed to food. Check for FDA approval to confirm it is non-toxic.

12. Food Safe Epoxy for Mugs

Food safe epoxy for mugs is used for creating or repairing drinkware. Make sure the epoxy is FDA-approved food-safe epoxy before using it with beverages.

13. Food Safe Epoxy Paint

Food safe epoxy paint is used to coat surfaces in food-contact areas. Always ensure the paint is safe for food use and fully cured to prevent harmful chemical exposure.

14. Food Safe Epoxy for Cutting Boards

Wood cutting boards are frequently sealed and protected with food safe epoxy.It is critical that the epoxy is non-toxic and safe for food once fully cured.

15. Food Safe Deep Pour Epoxy

Food-safe deep pour epoxy is ideal for projects where a thick layer of epoxy is required, like creating a resin countertop. These epoxies are formulated to be food-safe, but always confirm curing time and safety certifications.

16. Food Safe Epoxy Spray

food safe epoxy spray is often used for coating surfaces that will come into contact with food. Be sure it is labeled as FDA-approved for food contact.

17. Best Food Safe Epoxy Resin

The best food safe epoxy resin is one that is FDA-approved, fully cured, and non-toxic. Some well-known brands include Permabond and Max CLR, which offer high-quality, safe resins for food-contact applications.

18. Food Safe Epoxy for Tumblers

Drinkware is coated with epoxy to make it safe to use in food tumblers.Prior to use, make sure the epoxy glue is completely set and has a food-safe label.

19. Is Gorilla Glue Epoxy Food Safe?

Gorilla Glue epoxy is not inherently food-safe. It is primarily designed for general-purpose use, so if you plan to use it for food-contact applications, make sure it’s labeled as FDA-approved food safe epoxy.

20. Max CLR Epoxy Food Safe

Max CLR Epoxy is a crystal-clear, durable epoxy resin that can be used for food-safe applications, including countertops and drinkware, once fully cured.

21. Permabond Food Safe Epoxy

Permabond food safe epoxy is a high-performance adhesive designed to be safe for food-contact surfaces. Always check for proper curing instructions and FDA approval.

22. Permabond Food-Safe Epoxy Adhesives

Permabond food safe epoxy adhesives offer strong bonding for food-contact materials. These adhesives are FDA-approved, making them suitable for use in kitchens and food-related projects.

23. 2 Part Epoxy Food Safe

2-part epoxy resins are commonly used for food-contact applications like countertops, cutting boards, and drinkware. Be sure to choose one that is FDA-approved food-safe.

24. Are Epoxy Cutting Boards Food Safe?

Epoxy cutting boards can be food-safe if the epoxy used is specifically designed for food contact and is FDA-approved. Verifying the product’s safety label is crucial.

25. Art Resin Epoxy Food Safe

When properly labeled for food contact, art resin epoxy, which is used for craft projects, can be safe for consumption. Always check if it is FDA-approved before using it in food-related applications.

26. Best Food Safe Epoxy

The best food safe epoxy is a resin that is FDA-approved for food-contact applications, durable, and non-toxic once cured. Brands like Permabond and Max CLR are trusted options.

27. Ceramic Epoxy Food Safe

Ceramic epoxy food safe is ideal for bonding or repairing ceramic items used for food, such as bowls or mugs. Make sure the product has FDA approval for interaction with food at all times.

28. Clear Epoxy Resin Food Safe

Clear epoxy resin food safe is used for creating glossy, durable finishes on kitchen surfaces like countertops and cutting boards. Ensure the resin is FDA-approved and non-toxic.

29. Clear Food Safe Epoxy

Clear food safe epoxy is perfect for creating a glossy finish on items like countertops and drinkware. Ensure it is FDA-approved and safe once cured.

30. Devcon 5 Minute Epoxy Food Safe

Devcon 5-minute epoxy is fast-curing and can be used for certain food-contact applications if labeled as food-safe. Always check product specifications for FDA approval.

31. Easy Cast Epoxy Food Safe

Easy Cast epoxy is used for crafting and can be food-safe if it is specifically formulated for food-contact applications. Ensure that the product is fully cured before using with food.

32. Epoxy Countertops Food Safe

Epoxy countertops food safe are used to create durable, non-toxic kitchen surfaces. Choose an FDA-approved food-safe epoxy for kitchen countertops and make sure the epoxy is fully cured before use.

33. Epoxy Cutting Board Food Safe

Epoxy cutting boards can be safe for food if the epoxy resin is FDA-approved. To prevent any leaching, make sure the cutting board is securely sealed and cured.

34. Epoxy Food Safe Resin

Epoxy food-safe resin is designed especially for use on surfaces that come into touch with food, such as serving trays, cutting boards, and counters. Ensure it’s FDA-approved and fully cured.

35. Epoxy Glue Food Safe

Epoxy glue safe for food can be used for repairs or bonding food-related items. Always ensure that the epoxy is FDA-approved food-safe before use.

36. Epoxy Glue Safe for Food

Epoxy glue safe for food is specifically formulated to bond items that will be used for food contact. Verify that it is FDA-approved and completely cured.

37. Epoxy Putty Food Safe

Epoxy putty can be used for repairs in food-contact surfaces, but ensure the putty is FDA-approved food-safe before using it with food.

38. Epoxy That Is Food Safe

Epoxy that is food safe is an epoxy resin that is certified to be non-toxic and suitable for use with food once cured. Ensure it is labeled as FDA-approved.

39. FDA Approved Food Safe Epoxy

A resin that has passed safety testing and is non-toxic for surfaces in contact with food is known as FDA-approved food-safe epoxy. For utmost safety, make sure you adhere to the curing directions.

40. FDA Food Safe Epoxy

FDA food safe epoxy is epoxy that has been tested and approved by the FDA for food contact. Always check for FDA approval on the label before using it in food-contact applications.

41. FDA Food Safe Epoxy Resin

FDA food-safe epoxy resin is made to adhere to stringent FDA food safety regulations. Before the resin comes into touch with food, be sure it has fully dried.

42. Food and Heat Safe Epoxy

Food and heat-safe epoxy is ideal for surfaces exposed to high temperatures, such as countertops or cookware. Ensure the epoxy is FDA-approved for both food and heat resistance.

43. Food Safe 2 Part Epoxy

Food-safe 2-part epoxy is commonly used for creating durable, safe surfaces in food-related applications. Make sure the resin is FDA-approved food-safe and fully cured.

44. Food Safe Clear Epoxy

Food-safe clear epoxy is perfect for creating high-gloss, non-toxic coatings on food-contact surfaces like countertops or tumblers.

45. Food Safe Clear Epoxy Resin

Food-safe clear epoxy resin is used to create smooth, glossy surfaces that come into contact with food. Ensure the epoxy is FDA-approved and safe for food.

46. Food Safe Countertop Epoxy

Food-safe countertop epoxy is ideal for creating durable, non-toxic countertops in kitchens. Verify the product’s food safety certification at all times.

47. Food Safe Epoxy 3D Print

Food-safe epoxy for 3D printing can be used to coat 3D printed items that will be used for food-contact applications. Ensure the resin is FDA-approved for food use.

48. Food Safe Epoxy Amazon

Food-safe epoxy on Amazon can be found from several trusted brands. Be sure to check the FDA approval and use recommendations on the product page.

49. Food Safe Epoxy Coating

Food safe epoxy coating is used to protect and seal surfaces that come into contact with food, such as countertops, cutting boards, and tumblers.

50. Food Safe Epoxy Cutting Board

Wooden cutting boards are sealed with food safe epoxy to increase their durability and moisture resistance.

Here’s a table summarizing whether various types of epoxy are food safe:

| Epoxy Type | Food Safe |

| Epoxy Resin | Not food safe unless FDA-approved |

| Epoxy Safe for Food | FDA-approved required |

| Epoxy Countertops Food Safe | FDA-approved if fully cured |

| Gorilla Epoxy | Not food safe unless labeled FDA-approved |

| 2 Part Epoxy | FDA-approved if specified |

| Amazing Clear Cast Epoxy | FDA-approved if specified |

| Cured Epoxy | Safe if FDA-approved and fully cured |

| Cured Epoxy Resin | Safe if FDA-approved and fully cured |

| Devcon 5 Minute Epoxy | Not food safe unless FDA-approved |

| Devcon Epoxy | Not food safe unless FDA-approved |

| Envirotex Lite Epoxy | FDA-approved if specified |

| Epoxy Countertop Food Safe | FDA-approved if fully cured |

| Epoxy Food Safe After Curing | FDA-approved after curing |

| Epoxy Food Safe for Cutting Boards | FDA-approved if fully cured |

| Epoxy Food Safe Once Cured | FDA-approved after curing |

| Epoxy Glue | FDA-approved if specified |

| Epoxy Putty | FDA-approved if specified |

| Epoxy Resin Food Safe for Cutting Boards | FDA-approved if fully cured |

| Epoxy Resin Safe for Food | FDA-approved and fully cured |

| Famowood Epoxy | Not food safe unless FDA-approved |

| JB Weld Epoxy | Not food safe unless FDA-approved |

| Let’s Resin Epoxy | FDA-approved if specified |

| Liquid Glass Epoxy | FDA-approved if specified |

| Loctite Epoxy | Not food safe unless FDA-approved |

| Marine Epoxy | Not food safe unless FDA-approved |

| MAS Epoxy | Not food safe unless FDA-approved |

| MAS Table Top Epoxy | FDA-approved if specified |

| Resin Epoxy | FDA-approved if specified |

| Stone Coat Epoxy | FDA-approved if specified |

| Table Top Epoxy | FDA-approved if specified |

| Food Safe Epoxy | Yes, if FDA-approved |

| Food Safe Epoxy Resin | Yes, if FDA-approved |

| TotalBoat Epoxy | FDA-approved if specified |

| Two Part Epoxy | FDA-approved if specified |

| West System Epoxy | Not food safe unless FDA-approved |

Conclusion:

In conclusion, food safe epoxy is a crucial material for creating durable, attractive, and safe surfaces in food-related environments. It is specifically formulated to be non-toxic and resistant to heat, moisture, and chemicals, making it ideal for applications like countertops, cutting boards, and kitchen tools. food safe epoxy differs from regular epoxy by using non-toxic ingredients that prevent harmful substances from leaching into food, ensuring safety when properly cured.

When choosing and applying food safe epoxy, it’s essential to check for certifications such as FDA approval, carefully follow mixing and curing instructions, and ensure the epoxy is fully cured before use. Proper maintenance and care are also necessary to maintain the food safe epoxy qualities over time.

Final recommendation: Always ensure that the food safe epoxy is fully cured and take appropriate safety precautions during application. By following safety guidelines and choosing high-quality epoxy, you can enjoy a beautiful, functional, and safe food-contact surface for years to come.

FAQs:

1. Is epoxy resin food safe?

Answer: Epoxy resin is not generally food safe in its uncured form. However, some specific epoxies are labeled as food-safe after curing, such as Envirotex Lite and MAS Table Top Epoxy.

2. Is epoxy safe for food?

Answer: Epoxy is not inherently safe for food contact unless it is specifically labeled as food-safe by the manufacturer and fully cured.

3. Are epoxy countertops food safe?

Answer: Epoxy countertops can be food safe if the epoxy used is labeled as food-safe once cured. Products like Stone Coat and MAS Table Top Epoxy are designed for use on surfaces that come into contact with food after proper curing.

4. Is Gorilla Epoxy food safe?

Answer: Gorilla Epoxy is not food safe. It is designed for general use and is not recommended for applications that involve direct contact with food.

5. Is two-part epoxy food safe?

Answer: Some two-part epoxies can be food-safe, but you must check whether the product is specifically labeled as food-safe once cured, like Envirotex Lite.

6. Is Amazing Clear Cast epoxy food safe?

Answer: Amazing Clear Cast Epoxy is not inherently food-safe, but it can be food-safe once fully cured, provided it is used for non-food-contact applications as per manufacturer instructions.

7. Is cured food safe epoxy?

Answer: Cured epoxy can be food-safe, but only if the specific resin used is labeled as food-safe once fully cured. It is essential to follow the manufacturer’s curing guidelines.

8. Is Devcon 5-minute epoxy food safe?

Answer: Devcon 5-minute epoxy is not food safe. It is used for general repairs and bonding, but it is not designed for food-related applications.

9. Is Devcon food safe epoxy?

Answer: Devcon Epoxy is typically not food-safe. Like other general-purpose adhesives, it is not suitable for food-contact surfaces unless specified by the manufacturer.

10. Is epoxy countertop food safe?

Answer: Epoxy countertops are food-safe if the epoxy used is specifically labeled as food-safe after curing. Always ensure that the product is designed for food contact applications